Capability Overview

Process introduction

Process

Equipment capabilities

Equipment capabilities

Material capabilities

01

/06Capability Overview

As the world's largest supplier of turbocharged investment castings, Sinopei Digital Energy Powertrain Division is one of the main businesses of Sinopei Digital Energy at present and one of the main core business segments in the future

Process introduction

The investment casting process is capable of producing a wide range of complex workpieces and is suitable for almost all metal materials.

Its main features are as follows:

1. The dimensional accuracy of the casting is high and the surface roughness is small. The dimensional tolerance zone can meet the national standard CT4-CT6 class, or can meet the VDG-P690 standard D1-D3 class. The surface roughness can generally meet the requirements of Ra3.2-Ra6.3, and can be used directly without subsequent machining or only a small number of parts can be used to meet the use of

2. It can be applied to complex structural parts, or structures that are difficult to achieve or difficult to process by other processes, and the product weight is especially suitable for mass production castings

from a few g to a few kg 3. There are almost no restrictions on casting materials, especially for various high-melting alloys (various stainless steels, heat-resistant steels, high-temperature alloys, etc.) or various structures that are not easy to forge, weld or process

Its main features are as follows:

1. The dimensional accuracy of the casting is high and the surface roughness is small. The dimensional tolerance zone can meet the national standard CT4-CT6 class, or can meet the VDG-P690 standard D1-D3 class. The surface roughness can generally meet the requirements of Ra3.2-Ra6.3, and can be used directly without subsequent machining or only a small number of parts can be used to meet the use of

2. It can be applied to complex structural parts, or structures that are difficult to achieve or difficult to process by other processes, and the product weight is especially suitable for mass production castings

from a few g to a few kg 3. There are almost no restrictions on casting materials, especially for various high-melting alloys (various stainless steels, heat-resistant steels, high-temperature alloys, etc.) or various structures that are not easy to forge, weld or process

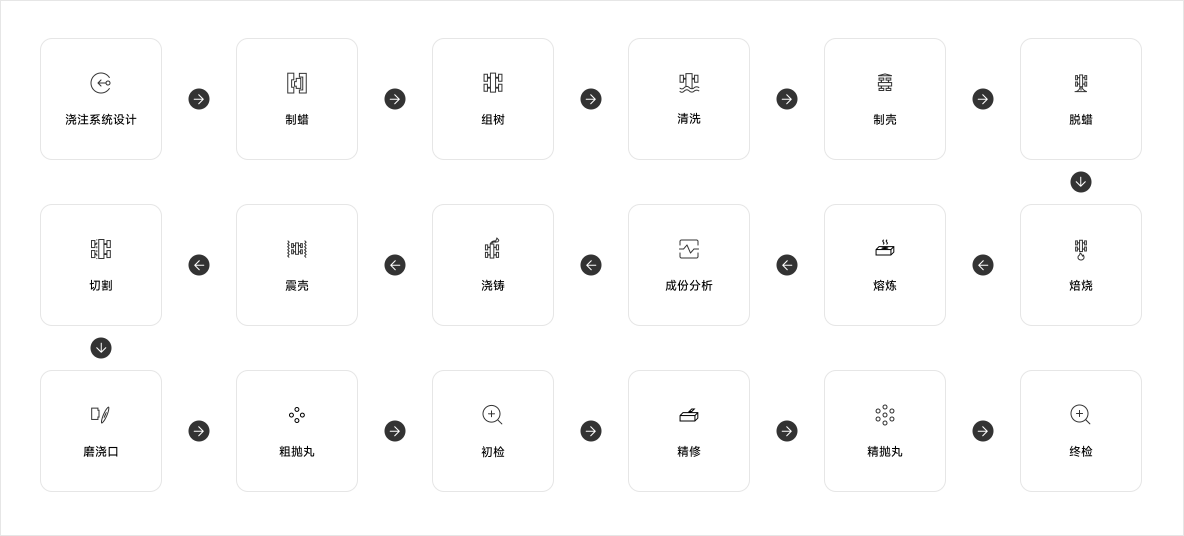

Process

Equipment capabilities

The reason why investment casting can become one of the near-net shape processes is inseparable from high-precision equipment, constant temperature and humidity workpiece environmental control, as well as engineers' mold design and manufacturing capabilities and gating system design capabilities. Our engineers ensure the high precision of the workpiece through high-quality equipment and strict process parameter control of each process

-

Shelling

-

Automatic catenary

-

Automatic wax injection machine

-

-

Shoot wax

-

Automatic catenary

-

Automatic wax injection machine

-

Equipment capabilities

-

Melt pouring

-

Vacuum fast-melting pouring

-

Atmospheric melting pouring

-

-

Melt pouring

-

Atmospheric melting pouring

-

Vacuum fast-melting pouring

-

Material capabilities

It can meet the requirements of various material specifications such as ASTM, SAE, AISI, ACI, DIN, EN, ISO and GB, and has the ability to produce various ferrous metal casting including stainless steel, alloy steel, high-temperature alloy, carbon steel and so on.

| material | classify | Detailed grades |

| stainless steel | Martensitic stainless steel | DIN 1.4021, ZG1Cr13, ZG2Cr13, etc |

| Ferritic stainless steel | Ferritic stainless steel | |

| Austenitic stainless steel | 1.4301\1.4305\1.4308\1.4541\CF8\CF8M\304\304L\316\316Ti, etc | |

| Precipitation-hardening stainless steel | 1.4542\17-4PH\15-5PH, etc | |

| Heat-resistant steel | Heat-resistant steel | 1.4845\1.4841\1.4826\1.4828\1.4837\1.48481.4980\1.4931\1.4923\SCH22\SCS13, etc |

| Superalloys | Ni-based superalloys | 2.4671/2.4632/2.4952/Inco713C/inco625/inco718/Mar 246, etc |

| Co-based superalloys | R30400, etc | |

| Fe-based superalloys | K13\K14, etc | |

| Carbon steel | Carbon steel, alloy steel | 42CrMo4\G20Si6\20Mn, etc |

KSLSON-M series of various austenitic, ferritic heat-resistant steels, high-strength cast steels, etc., developed by Sinopei

| M series | classify | Classification code | Classification name |

| M10 | Superalloys | M10 | Cobalt-based superalloys |

| M11 | Ni-based superalloys | ||

| M12 | Fe-based superalloys | ||

| M20 | Medium and high strength cast steel | M20 | Medium and high strength cast steel |

| M30 | Heat-resistant steel (alloy) | M30 | Pearlitic heat-resistant steel |

| M31 | Martensitic heat-resistant steel | ||

| M32 | Ferritic heat-resistant steel | ||

| M33 | High Ni austenitic heat-resistant steel | ||

| M40 | Low-Ni austenitic heat-resistant steel | M40 | Low-Ni austenitic heat-resistant steel |

Related Products

To learn more about Sinopec's services, contact us now

These cookies are indispensable for the website to function and you cannot turn them off in your system. These cookies are usually set only based on actions you take (i.e. requests for services), such as setting privacy preferences, logging in, or filling in forms. You can set your browser to block or prompt you for these cookies, but this may cause some website features to not work.